Multijunction PV Team

Multijunction SCs are conventionally used in a limited range of areas such as artificial satellites. We develop fabrication technologies to reduce the cost of these devices, as well as to reduce the weight and increase the power generation capacity of existing Si SCs.

SCs: Solar Cells

Research themes

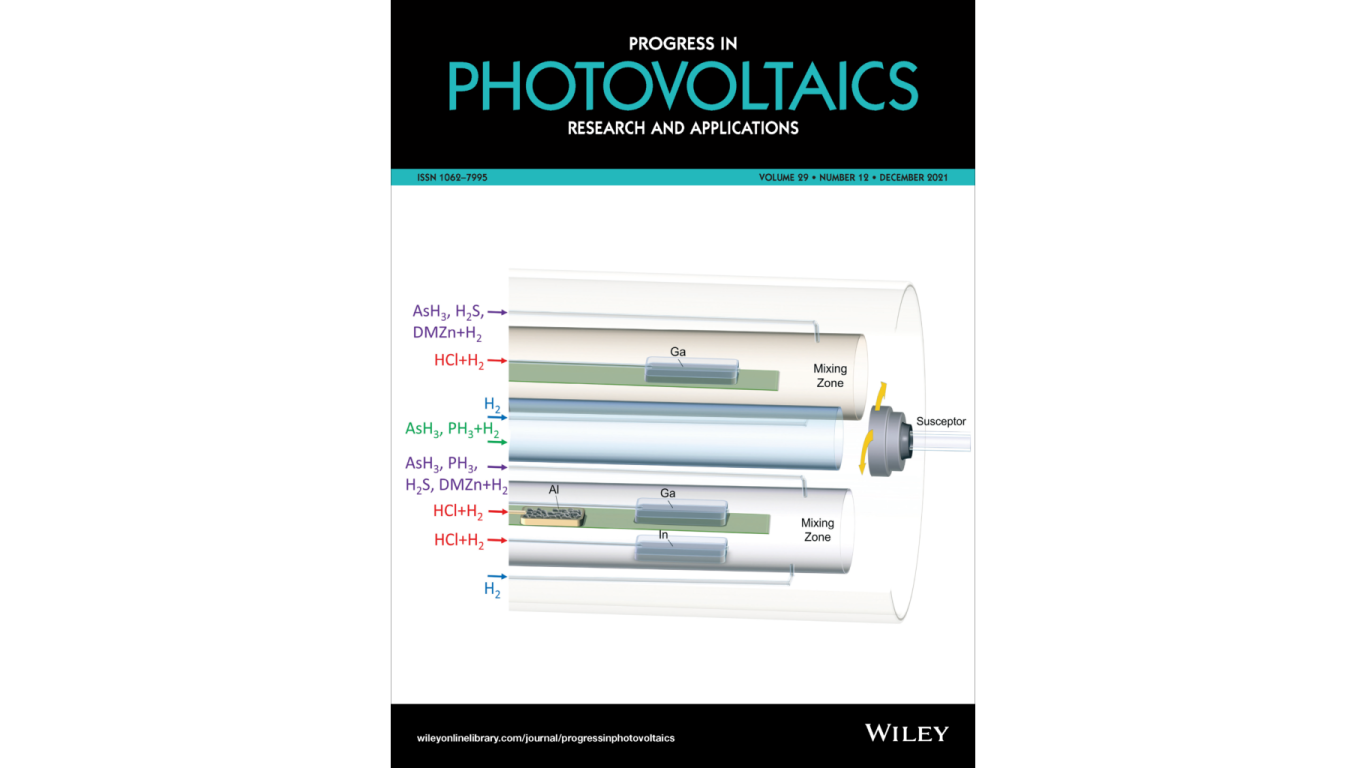

- R&D in low-cost fabrication techniques for ultra-high efficiency III-V semiconductor SCs (hydride vapor phase epitaxy)

- Work to realize low-cost bonding technology (smart stack) for various SCs

- R&D in lightweight and flexible CIGS SCs and minimodules

- R&D in wide- and narrow-gap CIGS SCs for multijunction applications

- Developments in chalcogenide energy conversion materials and devices such as SCs, radiation detectors, and water splitting hydrogen evolution

Research Team Leader / Greetings

SUGAYA Takeyoshi

Multijunction SCs featuring multiple combined cells are extremely efficient, but they have not been widely adopted due to restrictive manufacturing costs. Our Hydride Vapor Phase Epitaxy (HVPE) and smart stack technologies realize the low-cost manufacturing of multijunction SCs at an unprecedented level worldwide. We will further refine these technologies and introduce practical implementations.

Members

KAMIKAWA Yukiko

SHOJI Yasushi

NISHIDA Takeshi

ISHIZUKA Shogo

MAKITA Kikuo

MIYAMOTO Teruyuki

MATSUI Takuya

SAI Hitoshi

MIZUNO Hidenori

SVRCEK Vladimir

KOIDA Takashi

IIOKA Masayuki

KATOU Shunichi

KUMAGAI Hideo

TAKAHASHI Hideki

HIGUCHI Hirofumi

NAMIUCHI Chizu

FUJITA Akemi

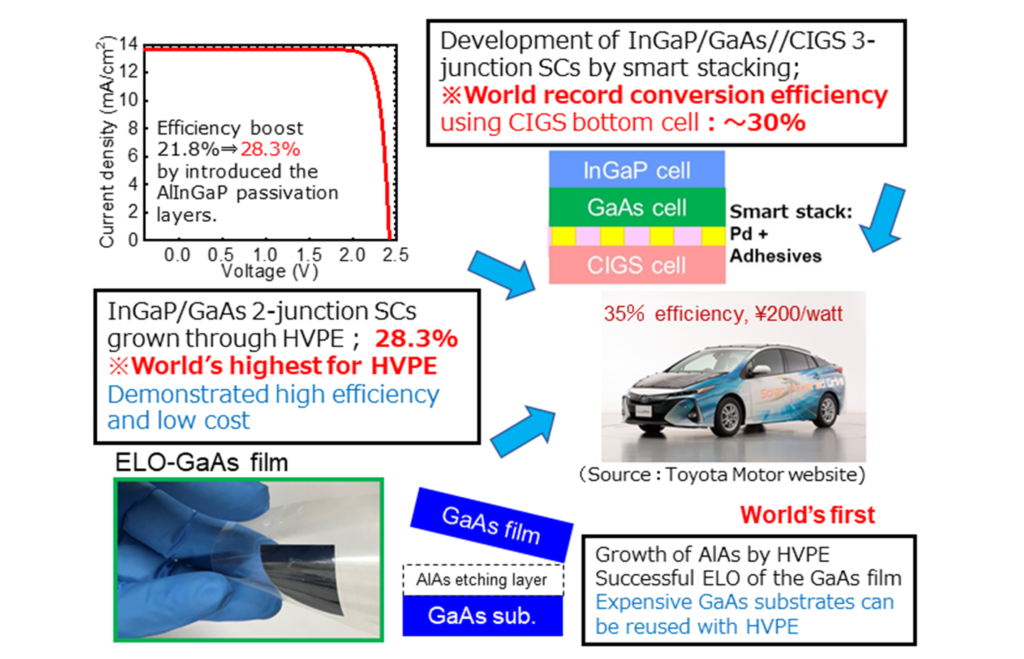

Low-cost Ⅲ-Ⅳ solar cells fabricated using hydride vapor phase epitaxy (HVPE) and smart stack technology

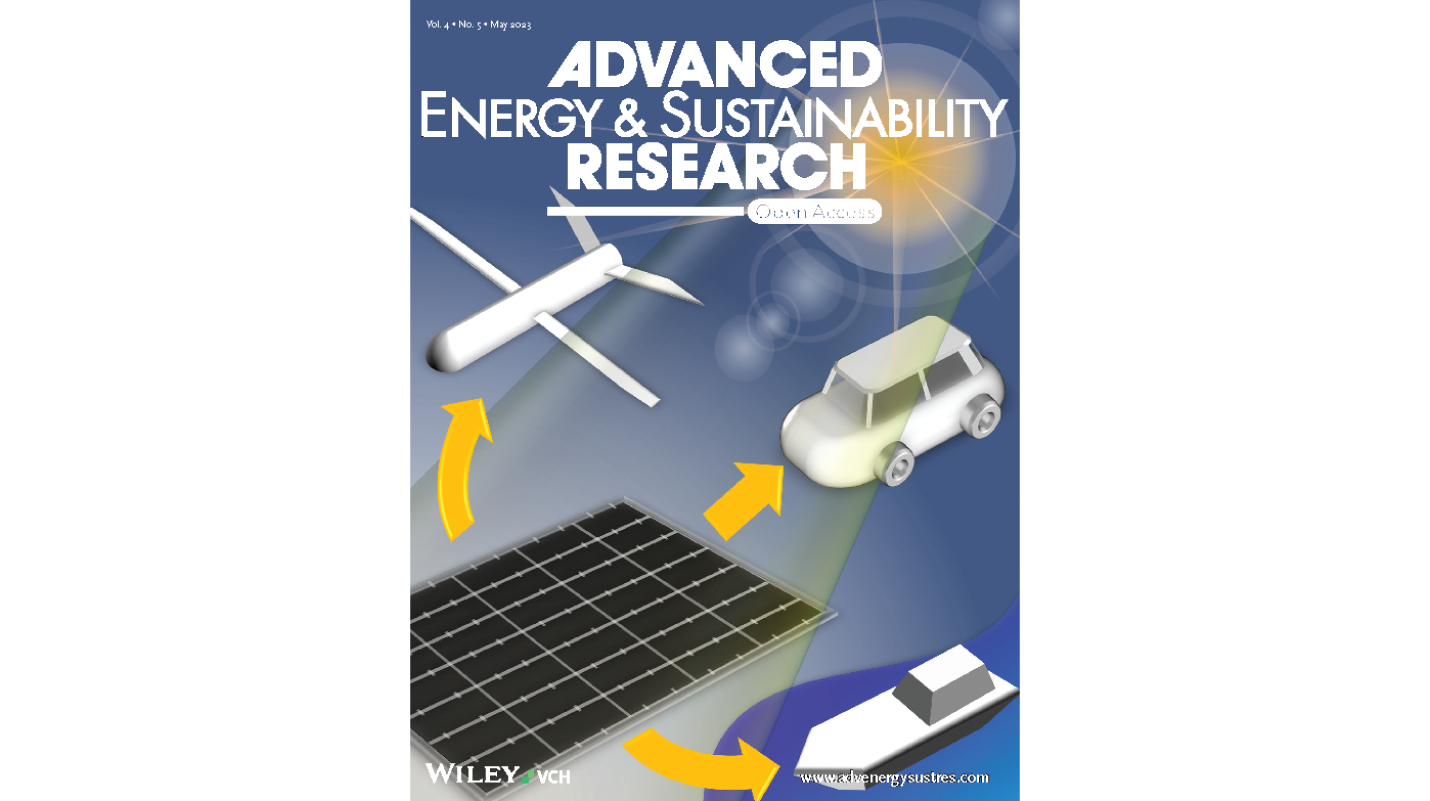

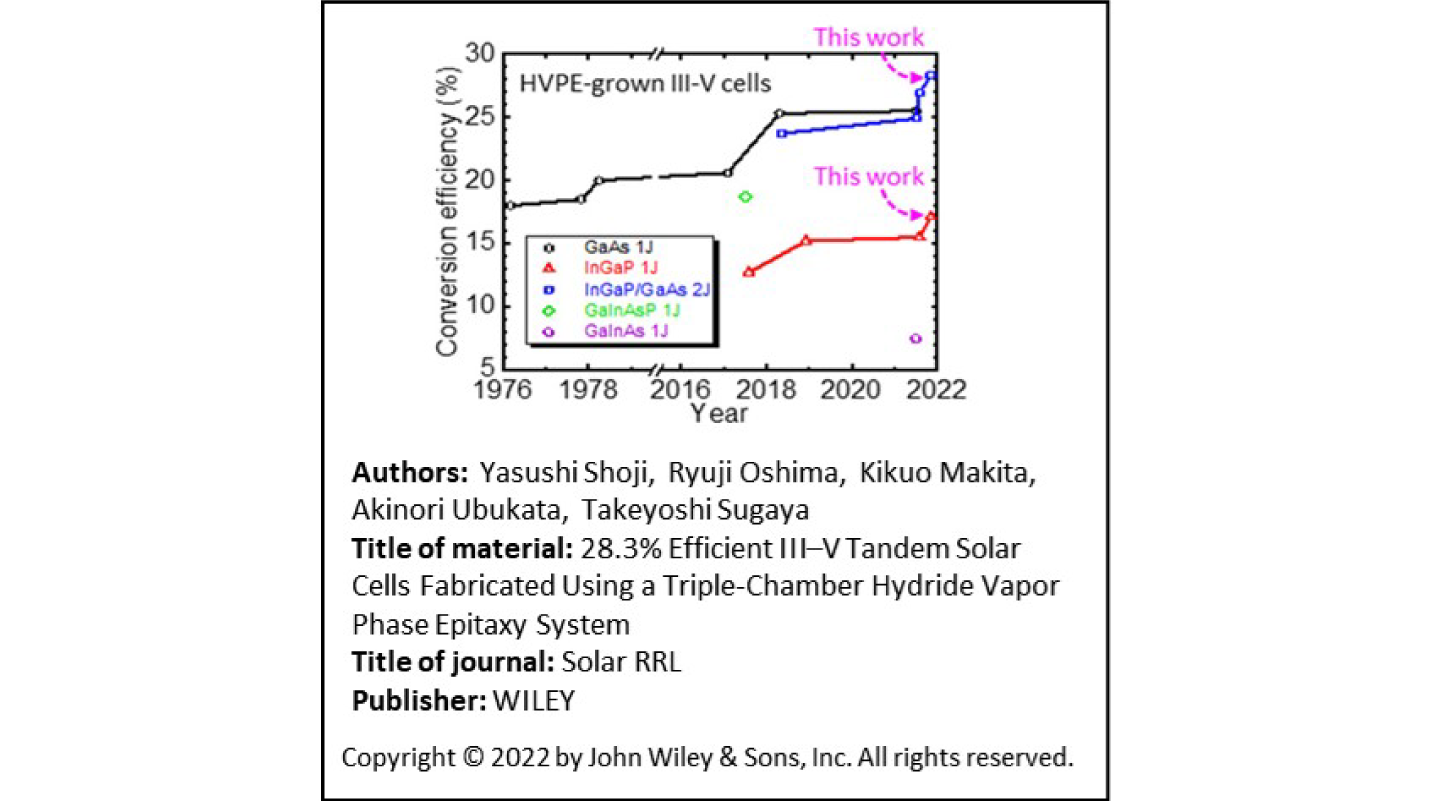

Multijunction SCs featuring multiple combined cells are extremely efficient, but they have not been widely adopted due to their manufacturing costs. We have been working on an epitaxial growth technology known as HVPE (hydride vapor phase epitaxy) which can grow materials at a cost of around a tenth of previous methods, and smart stack technology which is a low-cost bonding technique using low-cost bottom cells such as Si or CIGS. Our target is 35% for conversion efficiency and ¥200/W for the fabrication cost. We will be able to mount these SCs on unmanned aerial vehicles and cars.

We have achieved world record conversion efficiencies of 28.3% for HVPE grown SCs and 28.1% for CIGS based 3-junction SCs fabricated using smart stack technology.

Chalcogenide thin-film photovoltaics: applications for lightweight, flexible, and multi-junction solar cells and related energy conversion devices

CIGS (a generic term for chalcopyrite compounds consisting of Cu, In, Ga, and Se and related elements) and derivative chalcogenide-based photovoltaic (PV) thin-film solar cells and modules have numerous advantages which are different from those of conventional crystalline silicon PV technology, and thus, the development of new PV markets is anticipated. CIGS thin-film PV technology enables us to fabricate lightweight, flexible, and highly efficient solar cells and modules, which can be installed in places where weight restrictions are severe and surfaces are curved. Also, space use applications are highly likely because of the high tolerance of radiation of CIGS materials. In addition to photovoltaic solar cells and modules, a wide variety of high-performance energy conversion devices such as radiation detectors and photoelectrochemical water splitting hydrogen evolution are predicted with the use of CIGS-based materials.

To date, we have demonstrated an over 18.6% CIGS photovoltaic solar minimodule efficiency using a 17-cell monolithically interconnected structure (area: 68 cm2) on a lightweight and flexible substrate.

Video

Research

Highlights

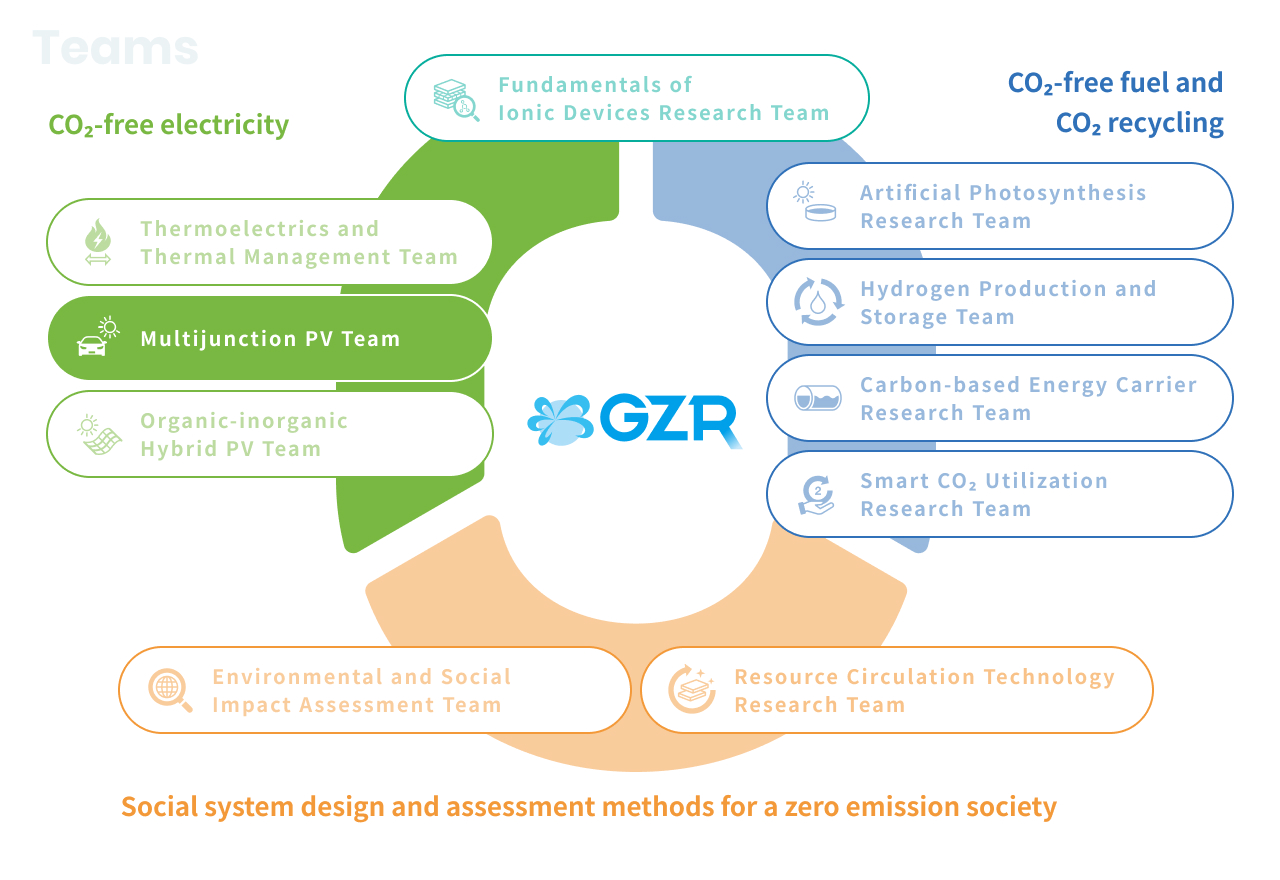

Research Teams

- Organic-inorganic Hybrid PV Team

- Multijunction PV Team

- Thermoelectrics and Thermal Management Team

- Fundamentals of Ionic Devices Research Team

- Artificial Photosynthesis Research Team

- Hydrogen Production and Storage Team

- Carbon-based Energy Carrier Research Team

- Smart CO2 Utilization Research Team

- Resource Circulation Technology Research Team

- Environmental and Social Impact Assessment Team